Home | HOME – new | Sektory | Manufacturing

Technology to optimize manufacturing processes

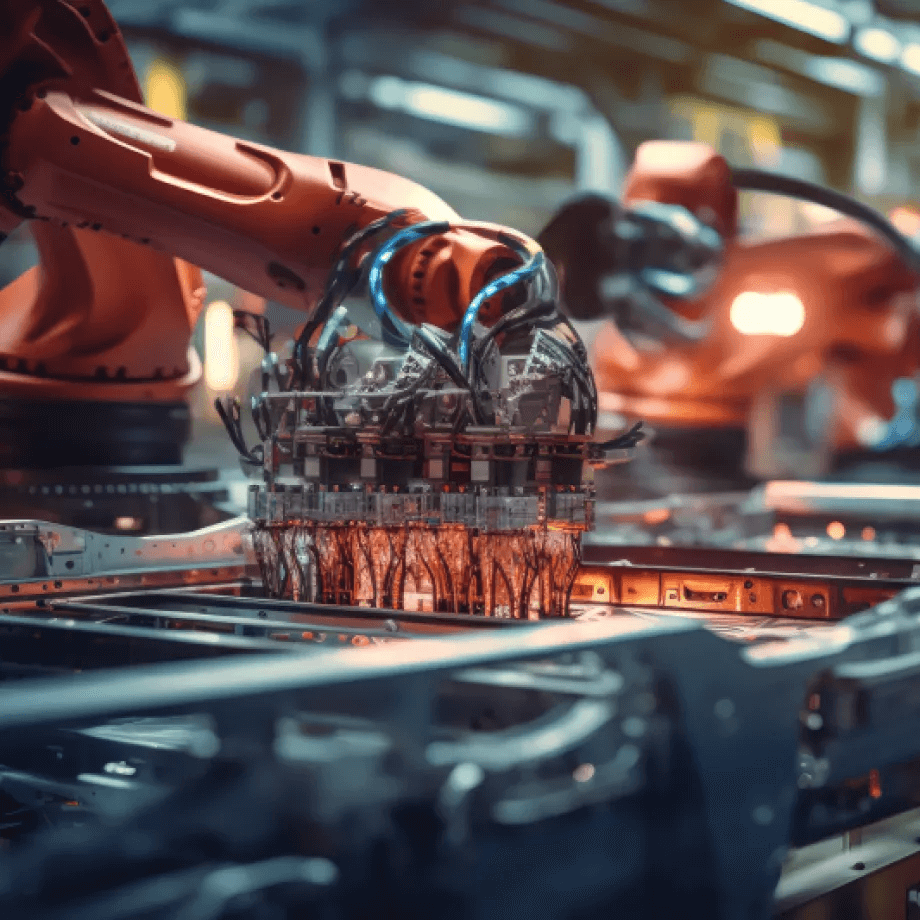

We transform your factory for Industry 5.0

#We are

different

Creating smart, efficient, and sustainable factories

Digital transformation is revolutionizing the entire value chain, requiring industrial companies to adapt rapidly to meet evolving demands and drive innovation, all while ensuring operational efficiency and sustainability.

At hiberus, we implement key technologies to transform traditional factories into smart, connected, adaptable, and sustainable operations. These solutions empower workers to make informed business decisions based on real-time data capture and monitoring.

„Over 15 years of developing and implementing Industry 4.0-based technologies.”

We provide you with the most innovative technology in the industry

Production management

We optimise the performance of production processes through comprehensive efficiency control: OEE, energy consumption and human resource management. We include full traceability and accurate mass balances to ensure a clear view of the production process.

Data Warehouse

A robust Data Warehouse is at the heart of Industry 5.0, collecting, storing and managing large volumes of data. This solution enables the integration and centralisation of all information, providing advanced real-time analytics, customised reporting and strategic decision support based on accurate and up-to-date data.

Quality control

In a production environment, any error, no matter how small, can quickly amplify and affect a large number of products. Continuous, automated quality control ensures early detection of faults, guaranteeing products and processes that meet the highest standards.

Inventory management

Inventory management and automation of raw materials, semi-finished and finished products is essential to avoid both overstocking and understocking. An automated and optimised system ensures a continuous flow of materials without overloading storage resources.

Predictive maintenance

Unexpected breakdowns can bring production to a halt, generating large losses. With a data-driven predictive maintenance plan and real-time condition analysis, failures can be predicted and prevented, minimising downtime and optimising equipment life.

Demand management

Accurate demand planning is key to aligning production with market needs. Forecasts based on data-driven intelligence avoid problems of overproduction or stock-outs, ensuring an agile response to fluctuations in demand.

Order management

The automatic integration of orders and delivery notes with ERP, EDI, CRM, etc., together with an efficient picking process, guarantees a high fulfilment rate, improving customer satisfaction and reducing logistical errors.

Improve your PRL

Occupational health and safety in industrial environments is a priority. The implementation of technological solutions makes it possible to improve working conditions, reducing risks, accidents and ensuring a safe and healthy production environment.

Sustainability

Using the necessary energy efficiently, optimising production processes, responsibly securing the origin of resources, ensuring compliance and expanding recycling processes are priority issues for a sustainable global business.